Screen printing is an age-old technique that has gained widespread popularity in a diverse range of industries. Whether it’s in the fashion industry or the advertising world, this printing method’s versatility and durability have made it a favorite among creators and entrepreneurs. However, with all its wonders, it can be a somewhat expensive venture, particularly if you’re just starting. Hence, learning to optimize supplies and save costs can be a game-changer. This blog post will unveil 10 screen printing hacks to help you get the most out of your supplies, and significantly save on costs.

DIY Screen Making

Let’s kick off with one of the simplest and most effective ways to save: DIY screen making. To start, you’ll need a wooden frame, mesh fabric, and a staple gun. First, cut the mesh to the size of your frame, leaving some extra for stapling. Stretch it over the frame, stapling it down as you go. Ensure the mesh is taut enough to bounce a little when pressed.

DIY screens are not only cost-effective but also highly customizable. You can make them in any size or shape you need, giving you greater flexibility over your designs. Plus, with proper care, these screens can be reused for many future prints, maximizing your savings.

Choose the Right Screen Mesh

The screen mesh plays a significant role in determining your print’s quality. Mesh count refers to the number of threads per inch. A higher count will give you finer details but less ink coverage, while a lower count provides thicker ink coverage but less detail.

Your choice of mesh count should be driven by your design’s complexity and your ink’s viscosity. For instance, detailed designs are better off with a high mesh count, while bold, less detailed designs can work well with a lower count. Familiarizing yourself with these dynamics can help you achieve superior print results while conserving your ink supply.

Proper Ink Usage

Speaking of ink, its usage is one of the biggest cost factors in screen printing. Luckily, several hacks can help you get the most out of it. First, buy only the best screen printing supplies. Secondly, only mix the amount of ink you need for the job at hand to avoid wastage. Then, use a hard plastic card to scrape off excess ink from your screen after every print. Additionally, learning how to thin your ink effectively can help you spread it further without compromising the print quality.

Master the Art of Registration

Registration is the alignment of your design across different color layers. For multi-color prints, mastering this art is crucial, or you’ll end up wasting materials on misprints. To achieve accurate registration, you can use registration marks on your screens. A lightbox can be handy in aligning these marks. Moreover, ensure that your screens are secured firmly during printing to prevent shifting and misalignments.

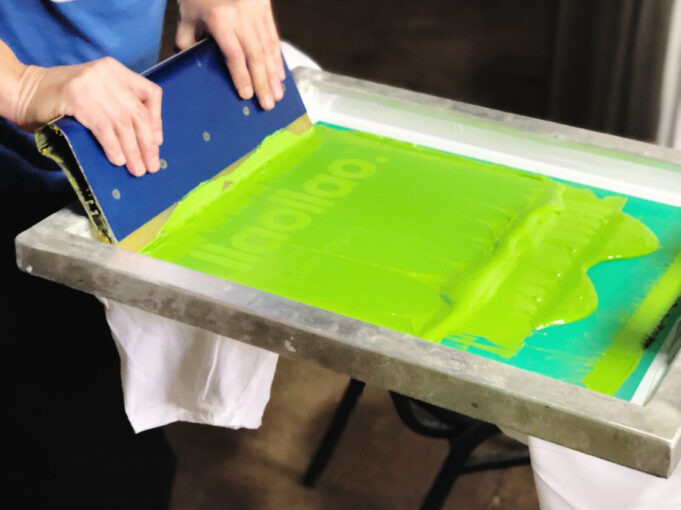

Optimize Squeegee Pressure and Angle

The squeegee pressure and angle greatly impact your ink coverage and, by extension, your print’s final look. Too much pressure can result in too much ink passing through the screen, leading to blotchy prints and unnecessary ink wastage. On the other hand, the right angle ensures the ink is pushed through the screen correctly.

A 45-degree angle is generally recommended. However, the optimal pressure and angle will often depend on your particular setup and design. It might take a bit of practice, but finding the sweet spot can enhance your print quality while conserving your ink supply.

Use the Right Emulsion

Emulsion is a photosensitive material that you apply to your screen to create the stencil for your design. There are several types of emulsion, each with its pros and cons, and suitability for various projects. For example, diazo emulsions are durable and economical, making them ideal for beginners and small-scale projects.

Knowing the right type of emulsion for your projects not only ensures high-quality prints but also reduces waste and saves costs. For instance, using a more expensive, high-resolution emulsion for a simple, low-detail design is unnecessary and uneconomical.

Proper Cleanup and Reclaiming Screens

Proper cleanup after printing can extend your screen’s life and maximize its usage. First, remove any excess ink with a scraper. Then, use a screen wash to remove the remaining ink. Afterward, apply an emulsion remover and scrub with a brush until the stencil is fully broken down. Rinely thoroughly to remove all residues.

Reclaiming your screens allows you to use them for multiple projects, significantly cutting down the costs of creating new screens for each print.

Opt for Eco-Friendly Options

Embracing eco-friendly options can also help you save costs while conserving the environment. For instance, water-based inks are not only easier to clean up but also require less harsh chemicals during the reclaiming process. Similarly, some emulsions are biodegradable and safe to rinse down the drain.

By opting for these eco-friendly alternatives, you save on cleanup supplies and avoid potential health and environmental hazards associated with traditional materials.

Utilize Scrap and Test Prints

Scrap and test prints don’t have to go to waste. They can be repurposed for various uses. For instance, you can use them for test runs to practice and perfect your technique. You can also use them for small-scale projects, promotional items, or even as unique packaging materials.

By finding innovative ways to utilize your scrap and test prints, you can minimize waste and get more value out of your materials.

Bulk Buying and Supplier Negotiation

Last but not least, consider buying your supplies in bulk. Most suppliers offer discounts for large purchases, resulting in significant cost savings over time. Additionally, don’t shy away from negotiating with your suppliers. Many are open to giving discounts to maintain good business relationships.

Remember, every cent saved on supplies can contribute to higher profit margins for your screen printing business.

Conclusion

Screen printing is indeed a rewarding venture, but it doesn’t have to break the bank. With the hacks shared above, you can significantly maximize your supplies, save costs, and enhance your efficiency. Remember, mastering these tips doesn’t happen overnight. But with patience, practice, and persistence, you’ll soon be reaping the benefits of cost-effective and efficient screen printing.