If you’re looking for a company that can provide custom aluminum extrusions, you’ve come to the right place. At our company, we specialize in creating high-quality extruded aluminum products for our customers. In this blog post, we will discuss what you need to know about custom aluminum extrusions.

We will cover everything from the different types of extrusion profiles to the various finishes that are available. We hope that this information will help you make an informed decision about which type of aluminum extrusion is best for your needs!

What Are Aluminum Extrusions and What Are They Used For?

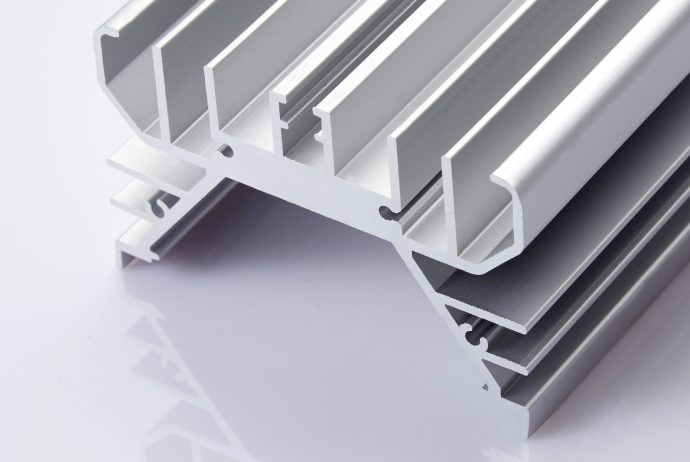

Aluminum extrusions are a type of aluminum profile that is created by forcing aluminum through a shaped die. This creates a long, thin piece of aluminum that can be used for a variety of purposes. Aluminum extrusions are often used in manufacturing and construction, and they can be found in a variety of different applications.

What Are the Different Types of Aluminum Extrusion Profiles?

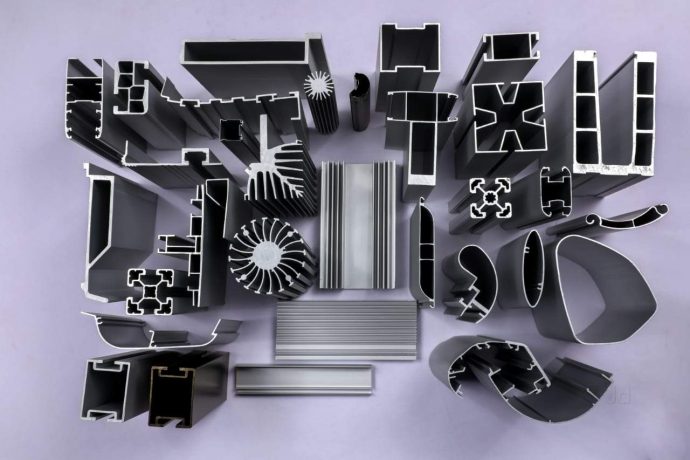

There are a number of different types of aluminum extrusion profiles, and each one has its own set of benefits and drawbacks. The most common types of profiles include:

- Square tubing: Square tubing is a simple, rectangular profile that is perfect for structural applications. It is strong and durable, and it can be easily machined and welded.

- Rectangular tubing: Rectangular tubing is similar to square tubing, but it has rounded edges instead of sharp corners. This makes it ideal for applications where safety is a concern.

- Round tubing: Round tubing is perfect for applications where strength and flexibility are important. It is less stiff than other types of tubing, but it is still very strong.

- Channel: Channel is a U-shaped profile that is often used for framing or structural applications. It is strong and durable, and it can be easily welded or machined.

What Are the Different Finishes That Are Available?

There are a number of different finishes that are available for aluminum extrusions, including:

Mill finish: Mill finish is the standard finish for aluminum extrusions. It is unfinished, and it has a dull appearance.

Anodized finish: Anodized finish is a coating that is applied to the exterior of the extrusion. It protects the metal from corrosion, and it comes in a variety of colors.

Powder coat finish: Powder coat finish is a coating that is applied to the exterior of the extrusion with powder paint. It protects the metal from corrosion, and it comes in a variety of colors.

How to Order Custom Aluminum Extrusions

Fonno Aluminium is a professional aluminum extrusion manufacturer with over 10 years of experience. We can provide you with custom aluminum extrusions according to your requirements. The process is simple and easy, just send us your drawings or samples, and we will produce the products you need.

We have a variety of surface treatments, such as anodizing, powder coating, and wood grain printing, which can make your products more durable and beautiful. In addition, we also have a team of experienced engineers who can provide you with technical support. So if you need custom aluminum extrusions, please don’t hesitate to contact us. We will be happy to serve you.

The Benefits of Using Custom Aluminum Extrusions

There are a number of benefits that can be attributed to using custom aluminum extrusions. Some of the most notable benefits include:

- Custom aluminum extrusions can be tailored to meet the specific needs of the customer. This ensures that the products are perfectly suited for the application, and it eliminates the need for modifications or adjustments.

- Custom aluminum extrusions are strong and durable. They can be used in a variety of applications, and they can withstand heavy loads without breaking or bending.

- Custom aluminum extrusions come in a variety of shapes and sizes. This allows for greater flexibility when designing products, and it makes it easier to find a profile that is compatible with the needs of the application.

- Custom aluminum extrusions are easy to install and use. They do not require any special tools or equipment, and they can be easily integrated into existing systems.

- Custom aluminum extrusions are cost-effective. They are typically less expensive than other types of materials, and they can be reused or recycled if necessary.

If you are looking for a material that is strong, durable, and flexible, then custom aluminum extrusions may be the perfect solution for you. Contact fonnovaluminium.com today to get started.

Things To Consider When Ordering Custom Aluminum Extrusions

When ordering custom aluminum extrusions, there are a number of things that you need to keep in mind. Some of the most important things to consider include:

- The dimensions of the extrusion: Make sure to provide the manufacturer with accurate measurements so that they can produce the correct size extrusion.

- The type of finish desired: Make sure to specify the type of finish that you want, so that the manufacturer can apply the appropriate coating.

- The type of application: Be sure to describe the intended use for the extrusion, so that the manufacturer can select the right materials and design.

- The budget: Make sure to discuss budgetary constraints with the manufacturer, so that they can recommend an appropriate price point.

By keeping these things in mind, you can be sure that you will receive the perfect custom aluminum extrusion for your needs.