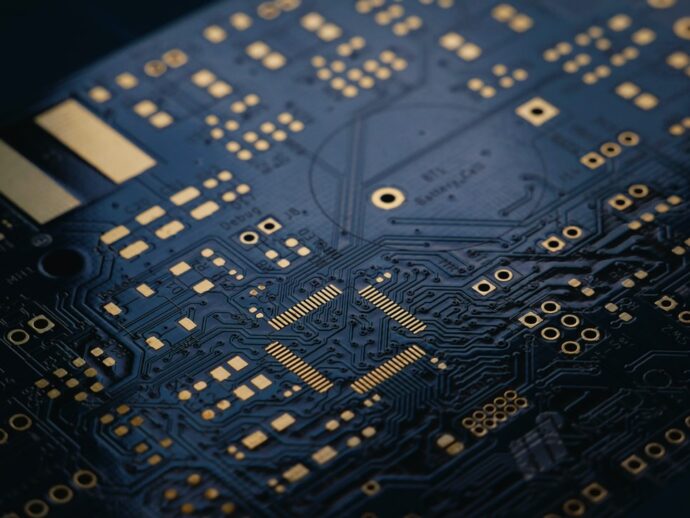

PCB is the main component of electronics. The acronym has also included circuit boards and printed circuit boards, both of which are the same thing. Considering the key role that these boards play in various things from computers to calculators, the material selection for PCB should be carried out with accuracy and proficiency for a given device’s electrical necessities. It is important to note the various materials of choice utilized in the process of designing and manufacturing printed circuit boards all have several advantages and disadvantages.

What does a printed circuit board mean?

A printed circuit board is a conductive design of an interlayer interconnection of copper film and prepreg (PP) using selective hole machining, etching of PCB materials, and electroplating. PCB materials are those that make printed circuit boards electrically connect, insulate circuits, and support. Printed circuit boards could be adapted to user requirements for all specifications. They can be found in many electronic devices, including many fields such as automotive industry, medical devices, lighting, industrial machinery etc.

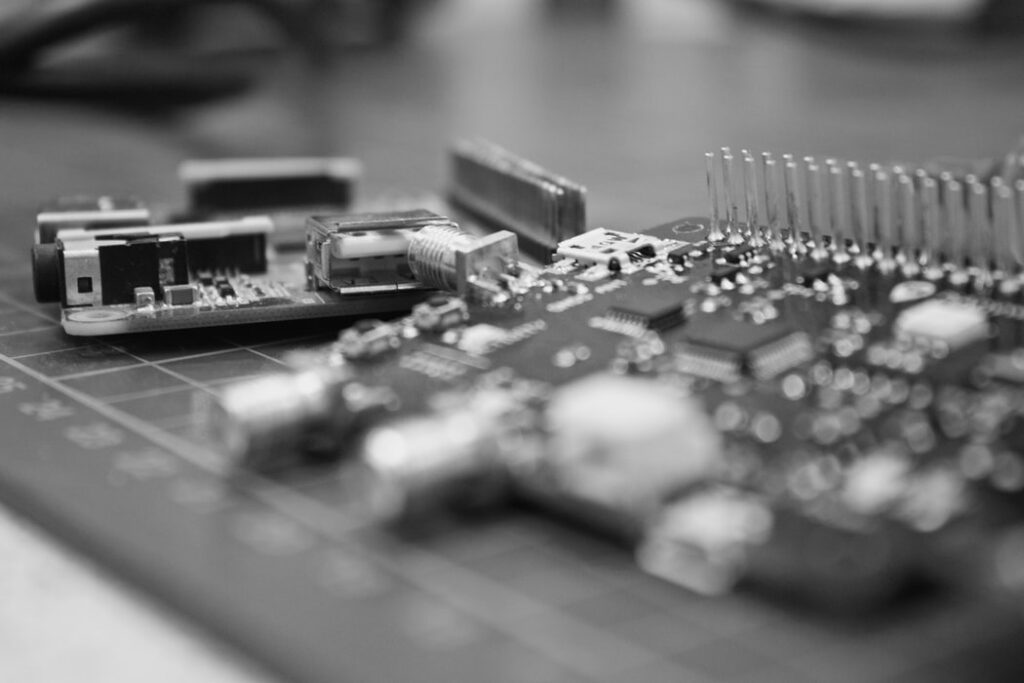

Various types of circuit boards are now available. You have to pick a suitable type of PCB for your specific application. In case you have more questions about PCB selection and want to know how much your PCB manufacturing would cost, visit pcbonline.com. There are seven major categories of printed circuit boards. The total number of layers and their flexibility degree determines these major categories of PCBs.

PCB layers

Single Layer PCB

A single-layer PCB is also referred to as a single-sided PCB. This PCB type is simple and is frequently used since these PCBs are easy to construct and produce. There is a layer of any conductive material coated on one side of this printed circuit board. Copper is usually applied as a conductive material for PCBs, given the fact that copper has very good conductive properties.

In order to protect the board from oxidation, a layer of solder mask should be applied, which is followed by a silkscreen to indicate all components on the board. Single-sided PCBs are commonly adopted in both commercial and educational projects since they are both easy to use and affordable. Single-sided PCBs have been widely used in vending machines, LED lighting, industrial relays, power supplies.

Double layer PCB

Double-sided PCBs provide an improved platform for circuit development. An upper and lower layer are both used to route signals, and thus making the overall size of the board smaller. As a result of decreasing the board’s size, the cost of a product may be reduced.

Layers of the printed circuit board are connected with vias. A via refers to a hole, which enables an electrical connection between a node from the upper side to the lower side of the PCB. Double-layer PCB is found to be more flexible, reasonably cheaper, and the main advantage of this type of PCB is its smaller size, making the circuit more compact. This PCB type is found in UPS systems, converters, telephone, amplifier, HVAC applications, power monitoring systems, and industrial controls.

Multi-layer PCB

Multilayer printed circuit boards include three or more sets of both conductive and dielectric layers. The conductive layers within the PCB are isolated with a dielectric layer; and they are interconnected by vias. This type of PCB construction is very intricate and applied to very complex and huge electrical tasks in limited space as well as compact circuits. It is used in great applications such as satellite system, file server, medical equipment, data storage, and GPS technology.

Different types of PCB materials including their uses

Aluminum PCB

There is an aluminum base core of the PCB, providing a high rate of heat dissipation from the PCB. Total efficiency and durability products are improved when the circuit cools down quickly with high efficiency. Also noteworthy is the mechanical strength in comparison to its overall weight. Aluminum PCBs benefit the environment due to the recyclable nature of aluminum, plus it advantages high-performance as well as heat-sensitive circuits.

Flexible PCB

Flexible printed circuit boards are also called flex circuits. This type of PCB consists of flexible plastic material such as polyimide, polyether ether ketone, or transparent conductive polyester film. Since the name implies, flexible PCBs are flexible and are able to be folded or flexed to a certain extent. In fact, as this is a very complex type of PCB, it includes different number layers. Flex circuits have wide usage in military, medical, and industrial applications.

Rigid PCB

Rigid PCBs consist of rigid material that prevents the PCB from twisting. Just like the flex PCB, the rigid PCB also has a different layer structure. The durability of this type of PCB is very long, and therefore it is used in many different elements of the computer, such as GPU, RAM, and CPU.

Rigid-flex PCB

Rigid-flex PCBs represent a combined design of rigid and flexible PCBs. This combination provides the ability to develop a mechanically complex design. Rigid-flex PCBs may take the place of an older, more traditional combination of rigid PCBs, cables and connectors. The reduction of mechanical connections increases the efficiency of the electrical contacts while the flexible part protects the circuit from mechanical dangers. Rigid-Flex printed circuit boards can be found in automotive, medical, aerospace, telecommunications, military, and industrial applications.

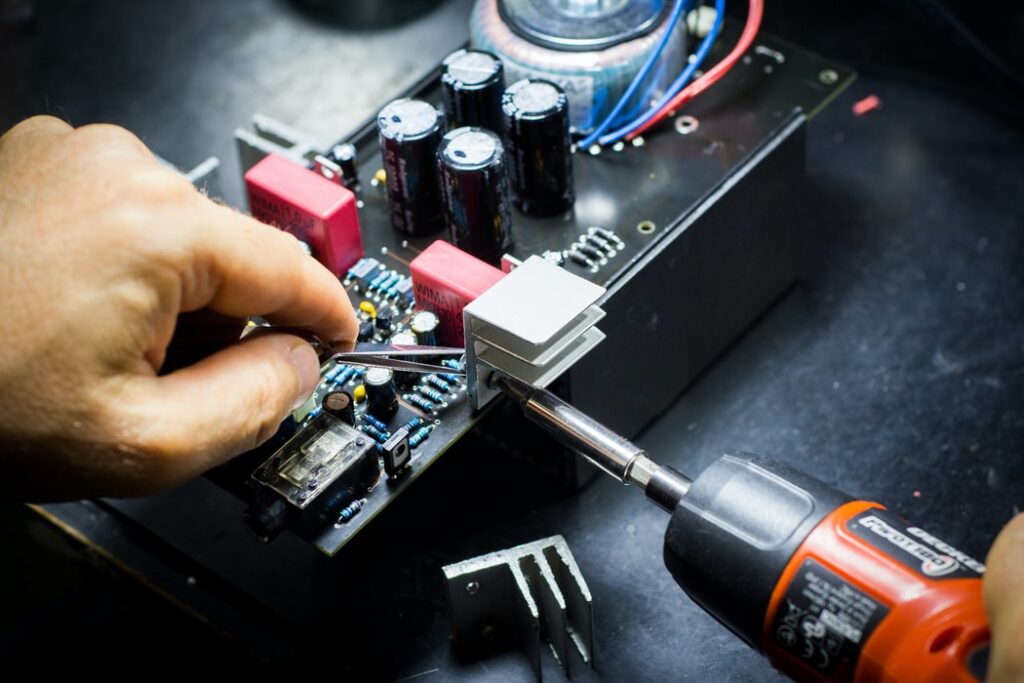

PCB Materials

FR4

FR is short for flame retardant. For all types of PCB manufacturing, FR4 stands out as the most used glass laminated material. FR4 is based on woven glass-epoxy compounds and is a composite material.

FR-1 and FR-2

This material is composed of paper and phenolic compounds, and it is used only for single-layer printed circuit boards. Both FR1 and FR2 have similar characteristics, except for the difference in the glass transition temperature.

CEM-1

This material consists of paper and two layers of woven glass epoxy and phenolic compounds. It is only used for single-sided printed circuit boards.

CEM-3

This material features a white-colored glass-epoxy compound primarily found in double-layer printed circuit boards.

Polyimide

This material is applied in flexible printed circuit boards. It is made of Rogers, Keepon, and Dupont. In addition, this material provides good electrical performance, a wide temperature range, bliss and high chemical resistance.

Prepreg

Prepreg stands for pre-impregnated. It refers to a glass fiber impregnated with resin. When heated, these pre-dried resins flow, stick and are fully immersed. Prepreg has a sticky layer that provides strength comparable to FR4. This material is also present in high glass transition temperature as well as halogen-free.

Quality is of utmost significance when choosing PCB materials for the designs of all types of PCBs, no matter whether their purpose is for home electronics or industrial equipment. When it comes to a certain item that includes a printed circuit board, it could be big or small, and inexpensive or high-priced. Furthermore, what is considered most important is that the item concerned offers outstanding levels of superior performance throughout its expected operating life.